Foundation — Book IV: The Calculus of Compromise (COPQ)

A chronicle on the Cost of Poor Quality, and why the most expensive bugs are the ones you choose to afford.

TL;DR: The Cost of Poor Quality (COPQ) framework translates technical debt and defects into a financial ledger with four accounts: Prevention, Appraisal, Internal Failure, and External Failure. Leaders who master this calculus shift quality from a cost center to a predictable driver of revenue and operational stability, proving that the most profitable investment is in preventing decay before it starts.

Introduction: The Unseen Ledger of Decay

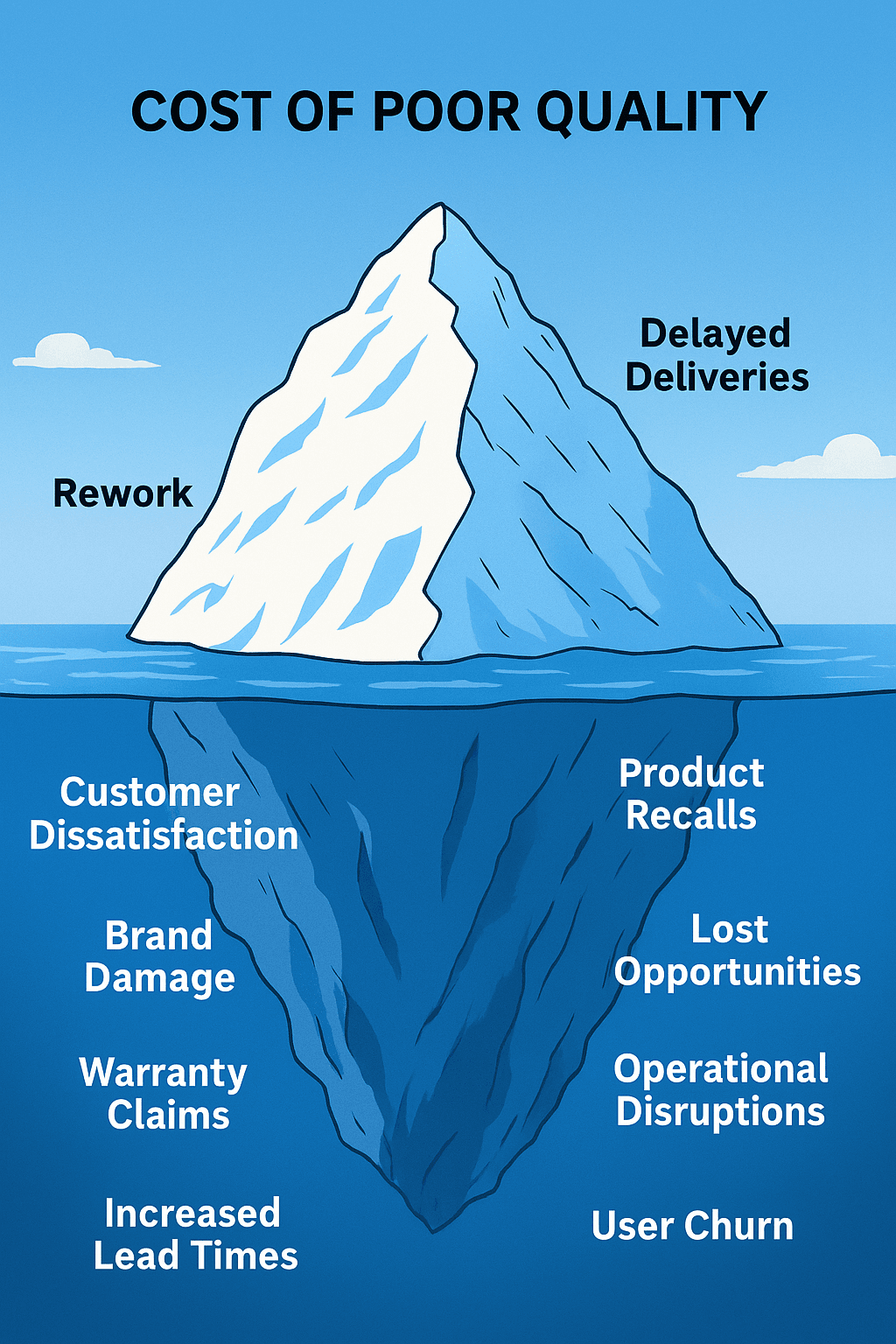

In the archives of fallen software empires, the story is always the same. Growth begets complexity, and complexity, if left untended, begets decay. This decay is not sudden; it is a slow accumulation of compromises—a skipped design review, a deferred refactor, a "good enough" test. For a CEO or CTO, these individual decisions seem trivial, but they are entries in an unseen ledger, and the debt they accrue is paid with interest in the form of emergency patches, customer churn, and lost revenue. This is the technical debt trap that can sink even the most promising startups.

To lead a complex system, you must speak the language of its economics. The Cost of Poor Quality (COPQ) framework is that language. It is a foundational principle that moves quality from the abstract realm of "good practice" to the concrete world of a balance sheet. It provides leaders with a calculus to measure the financial consequences of their choices, shifting the core strategic question from "How much does quality cost?" to "How much are we paying for the lack of it?"

The Four Entries in the Ledger of Quality

The COPQ framework, championed by quality pioneers like Philip Crosby, dissects all quality-related spending into four distinct categories. Understanding this balance is the key to mastering the economics of software delivery.

1. Prevention Costs: Fortifying the Gates

These are the proactive, strategic investments made to stop defects from ever being created. They are the most powerful and highest-leverage entries in the quality ledger.

- In Practice: This includes time spent on rigorous requirements gathering, architectural design reviews, developer training on secure coding, and building robust, automated deployment pipelines. As Martin Fowler has long argued, practices like Continuous Integration are fundamentally prevention activities that lower the cost of change.

Investing in prevention is the purest form of "shifting left." It is the deliberate act of building fortifications to ensure that entire classes of problems are eliminated by design. While these costs are incurred upfront, they drastically reduce the chaotic and expensive failures that plague unprepared organizations. This includes implementing robust testing practices like those outlined in Foundation Book I: The Three-A Problem.

2. Appraisal Costs: The Sentinels on the Wall

Appraisal costs are incurred to detect defects that have already been introduced. This is the work of inspection and verification—the sentinels patrolling the walls of the citadel.

- In Practice: This category includes all test execution (manual and automated), code reviews, security scans, and the maintenance of test environments and data.

Appraisal is necessary, but a high appraisal cost is often a symptom of insufficient prevention. If you are spending a fortune on an army of sentinels, it may be because the gates themselves were poorly built. The goal is not to eliminate appraisal, but to make it ruthlessly efficient, catching the few issues that slip past strong preventative measures.

3. Internal Failure Costs: The Rework Within the Citadel

These are the costs of defects found before a product reaches the customer. They represent the internal churn and wasted effort that happens behind the firewall—the cost of fixing cracks discovered within the citadel walls.

- In Practice: This is the time your engineers spend on rework, re-testing fixed bugs, and debugging failures found in staging. A recent Cloudflare post-mortem of a minor outage highlighted the significant internal engineering hours required for diagnosis and remediation—a classic example of internal failure costs that were managed before they could impact customers.

Every dollar spent on internal failures is a dollar not spent on innovation. It is a direct tax on your team's velocity and a leading indicator of friction in your development process.

4. External Failure Costs: The Price of a Breach

By far the most dangerous and expensive category, external failure costs are incurred when a defect escapes to production and impacts your customers. This is the cost of the citadel's walls being breached.

- In Practice: This includes the direct cost of production incidents, SLA penalties, increased customer support loads, and regulatory fines. More devastatingly, it includes the indirect costs of reputational damage, customer churn, and lost sales. As Sarah Choi of Greylock recently noted, unaddressed tech debt is a "silent tax" that can sink a startup, often by manifesting as crippling external failures.

These are the costs that make headlines. As observability expert Charity Majors notes, the real money is in preventing incidents entirely, because the cost of an external failure can erase months of hard-won progress. For a deeper dive into how outages can vaporize millions in minutes, see our analysis in Test Wars Episode VI: The Outage Awakens.

The Leader's Gambit: Shifting from Cost to Investment

The COPQ framework empowers a leader to reframe the entire conversation around quality. By categorizing activities, you can build a business case that even the most skeptical CFO can understand. The calculus is simple: every dollar invested in Prevention saves $10 in Internal Failure costs and $100 in External Failure costs.

The legendary W. Edwards Deming once said, "If you can't describe what you are doing as a process, you don't know what you're doing." COPQ provides the process for managing the economics of quality. It allows you to see if you are running a reactive, high-cost "failure factory" or a proactive, high-leverage "prevention culture."

Conclusion: Teach One Thing

Quality is not an expense; it is an economic model that governs the stability and profitability of your entire technology stack. The Cost of Poor Quality framework is the essential tool for understanding and managing this model. Your first step as a leader is to make these invisible costs visible. Start a conversation with your engineering and product leaders. Ask them to map your team's current activities onto these four categories.

The simple act of creating this ledger will reveal where your resources are truly being spent. In the calculus of compromise, the only winning move is to invest in integrity from the start. The empires that endure are not those that react to crises, but those that build systems to prevent them.

References

- What is Cost of Quality (COQ)? - American Society for Quality (ASQ). asq.org

- How to Estimate the Cost of Quality in Software Development in 2025 - Brainhub. brainhub.eu

- What is Cost of Quality (CoQ)? Tips for Managing Production... - Tulip Interfaces. tulip.co

- Is Quality Assurance a Waste of Money? - Harlequin Et Cie Substack. substack.com

- Philip Crosby, "Quality is Free" - ASQ. books.google.ch

- Continuous Integration - Martin Fowler. martinfowler.com

Related Posts

Foundation Book V: The Handoff Zone

The handoff zone is where your business logic goes to die. Learn how to track and validate business flows across backend-frontend boundaries with Business-Use framework.

Foundation Book II: WAGC Axe Engine

WCAG is the canon, axe is the engine—yet the green check is not the truth. Learn why compliance requires governance, design discipline, and human review.

Foundation Book I: The Three-A Problem

AAA structures tests; BDD defines acceptance. Learn how to use both to raise quality and speed delivery across teams.